The Importance of the Main Hydraulic Pump in Heavy Machinery

The main hydraulic pump is an essential component in hydraulic systems used across various industries, from construction to manufacturing. Understanding its functionality, maintenance, and role in the broader context of hydraulic machinery is crucial for business owners and decision-makers. In this article, we will delve into the intricacies of the main hydraulic pump, highlighting its importance, common issues, and best practices for maintaining optimal performance.

What is a Hydraulic Pump?

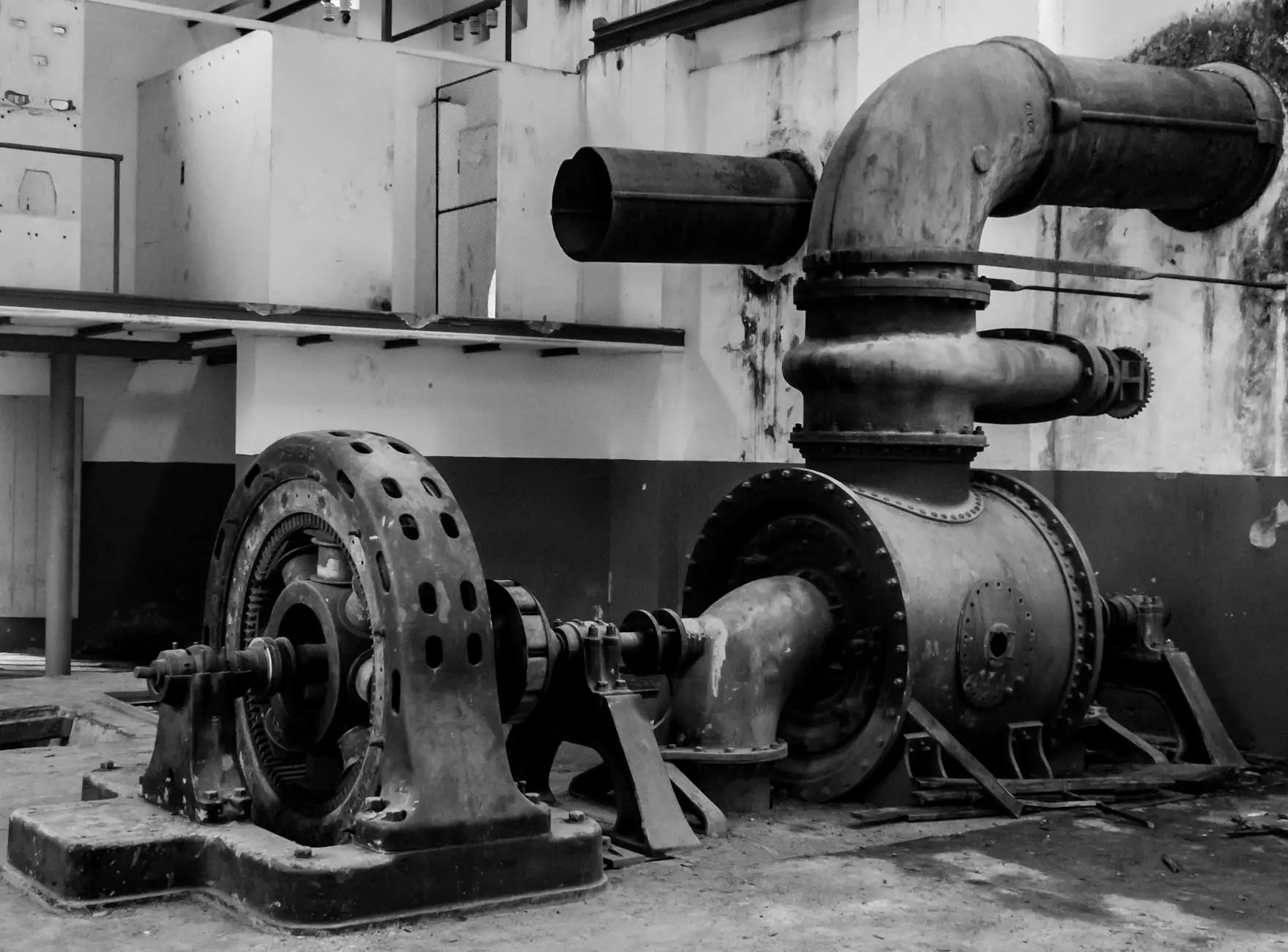

A hydraulic pump is a device that converts mechanical energy into hydraulic energy. This energy is used to generate fluid flow in hydraulic circuits. In many heavy-duty applications, the main hydraulic pump is the cornerstone that enables machines to perform vital tasks efficiently.

Types of Hydraulic Pumps

- Gear Pumps: Often used for their simplicity and reliability, gear pumps utilize gears to move fluid. They are ideal for low-pressure applications.

- Piston Pumps: These pumps are capable of generating high pressure and are often used in demanding applications. Piston pumps offer efficient and versatile performance.

- Vane Pumps: Vane pumps employ a rotating mechanism to transport fluid. These are typically used in hydraulic systems requiring variable flow and pressure.

Why is the Main Hydraulic Pump So Vital?

The main hydraulic pump acts as the heart of the hydraulic system, distributing hydraulic fluid to various components, including actuators and valves. Here are several key reasons why it is vital:

1. Ensures Efficient Power Transfer

The main hydraulic pump is responsible for converting the engine's mechanical power into hydraulic energy, which then operates numerous hydraulic devices, including lifts, cranes, and hydraulic cutters. This process ensures that machines operate smoothly and efficiently, maximizing productivity.

2. Enhances Performance and Reliability

In industries where heavy machinery plays a pivotal role, the reliability and performance of equipment are non-negotiable. A high-quality hydraulic pump guarantees consistent performance, preventing downtime and costly repairs.

3. Provides Versatility in Applications

The main hydraulic pump allows various machines to perform a wide range of functions using a single hydraulic system. For businesses involved in different sectors—from construction to automotive repair—having an understanding of hydraulic pumps can streamline operations and reduce costs.

Common Challenges Faced with Hydraulic Pumps

While the advantages of the main hydraulic pump are numerous, they are not without challenges. Here are some common issues that can affect the performance of hydraulic pumps:

1. Contamination of Hydraulic Fluid

Hydraulic systems are particularly sensitive to contamination. Dirt, debris, and water in hydraulic fluid can lead to pump failure. Regular maintenance, including fluid analysis and filtration, can help mitigate these risks.

2. Wear and Tear

Over time, components of the hydraulic pump will wear down due to friction and heat. Routine inspections and timely replacements are necessary to maintain operational integrity and longevity.

3. Leaks

Leaks are detrimental to hydraulic systems and can lead to loss of pressure and efficiency. Identifying and fixing leaks promptly is crucial to prevent economic loss.

Best Practices for Maintaining Your Main Hydraulic Pump

Effective maintenance of the main hydraulic pump not only extends its lifespan but also ensures optimal performance. Below are some best practices that every business should adopt:

1. Regular Fluid Checks

Perform consistent checks on hydraulic fluid levels and quality. Replace fluids based on manufacturer recommendations or as soon as contamination is detected.

2. Routine Inspections

Schedule regular inspections of the hydraulic system, focusing on the pump, hoses, and connections to identify potential issues before they become significant problems.

3. Keep It Clean

The cleanliness of the hydraulic pump and its components is vital to performance. Ensure that all surfaces are free from leaks and contamination, and maintain a clean work environment.

Upgrading Your Hydraulic Pump: When and Why?

It may be beneficial to upgrade your main hydraulic pump under certain circumstances, such as:

1. Increased Load Requirements

If your operations require additional power or capabilities beyond what your current pump can provide, an upgrade may be necessary. Newer models often feature improved efficiency and technology.

2. Obsolete Technology

As technology advances, older hydraulic pumps may become obsolete, lacking the features of newer models that improve performance and reduce energy consumption.

3. Cost Efficiency

In the long run, investing in a modern hydraulic pump can result in significant savings due to decreased maintenance costs and improved energy efficiency.

The Future of Hydraulic Pumps in Business Operations

The world of hydraulic technology is evolving rapidly. As industries strive for greater efficiency and sustainability, the role of the main hydraulic pump remains crucial. Innovations such as smart hydraulic systems equipped with sensors and predictive maintenance technologies are paving the way for enhanced performance metrics.

1. Automation and Smart Hydraulics

With the rise of automation, hydraulic systems are becoming more interconnected with other data-driven technologies. This allows for real-time monitoring and optimization.

2. Sustainability Efforts

As industries focus on reducing their carbon footprint, advancements in hydraulic technology will contribute to more environmentally friendly operations. Improved hydraulic pumps can enhance fuel efficiency and reduce wasted energy.

Conclusion

In conclusion, the main hydraulic pump serves as an indispensable asset in various industrial applications. By understanding its functions, challenges, and maintenance strategies, businesses can enhance their operational efficiency and ensure their machinery operates at peak performance. For those interested in high-quality hydraulic components, Shop Hydraulic America offers a variety of products including auto parts and motorcycle parts, ensuring that you have access to everything you need for optimal hydraulic performance.

Understanding the intricacies of the main hydraulic pump not only enhances productivity but also drives business growth in an increasingly competitive market. Stay informed, maintain your equipment, and watch your operations thrive.